When it comes to modern textiles, the process of two-component heated vulcanization plays a crucial role in defining the performance characteristics of anti-slip polyester functional fabric. This innovative method not only enhances the durability of the fabric but also significantly improves its elasticity, making it a favored choice for a wide range of applications. By combining liquid silicone rubber with a high-quality polyester base, manufacturers create a material that meets the demands of both everyday use and specialized environments.

The two-component heated vulcanization process involves mixing two distinct components that, when heated, undergo a chemical reaction. This reaction results in a cured, stable material that exhibits excellent performance traits. As the components blend under heat, they form a cross-linked structure that enhances the fabric’s overall resilience. This cross-linking is essential because it allows the fabric to maintain its shape and structure even under repeated stress and deformation, which is particularly vital in high-traffic areas where wear and tear are common. Traditional fabrics often suffer from issues like sliding, deformation, or mold growth over time; however, the anti-slip polyester fabric, thanks to this advanced vulcanization process, effectively overcomes these challenges.

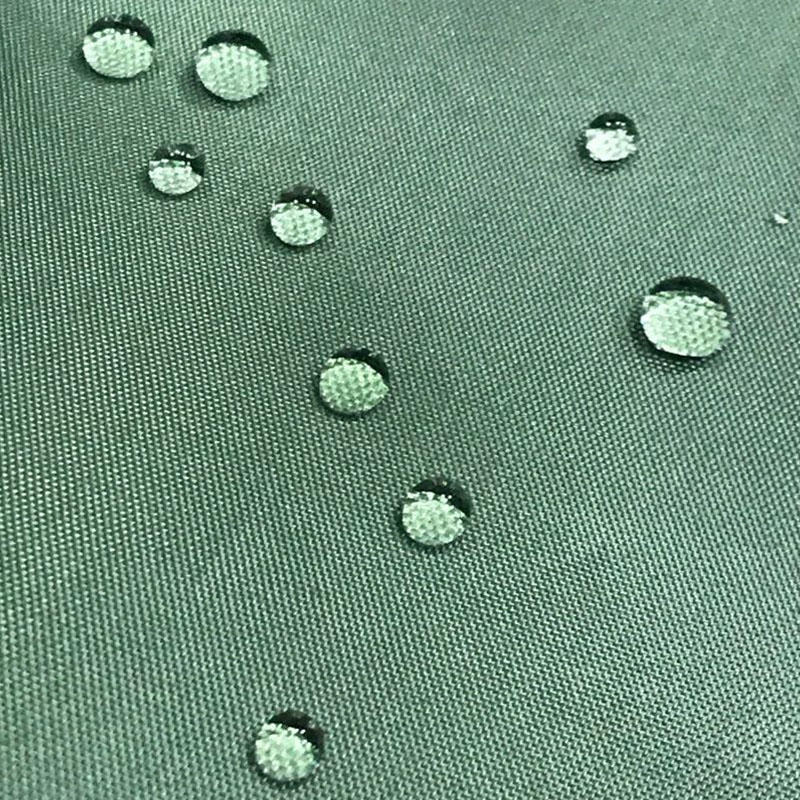

Moreover, the elasticity provided by the vulcanization process is a standout feature that elevates the usability of the fabric. When cured, the silicone rubber transforms into a soft, flexible material that retains a high degree of stretchability. This elasticity is essential not just for comfort but also for the fabric's functionality. It allows the material to conform to various surfaces and shapes, providing a snug fit that enhances its non-slip properties. The combination of high elasticity and anti-slip functionality means that the fabric can be used in various applications, from household items to sports and leisure gear, where safety and comfort are paramount.

Beyond its physical properties, the durability imparted by the vulcanization process ensures that the anti-slip polyester functional fabric remains reliable in a multitude of settings. Whether it's being used in a busy kitchen, a gym, or during outdoor activities, the fabric's resistance to moisture and oil makes it easy to clean and maintain. Its robust nature helps prevent issues such as mildew and moth infestations, which can plague traditional fabrics, further extending the lifespan of the product. As a result, manufacturers and consumers alike can enjoy the peace of mind that comes with investing in a material designed for longevity and performance.

In essence, the two-component heated vulcanization process is a game-changer in the production of anti-slip polyester functional fabric. By enhancing both durability and elasticity, it addresses the common challenges faced by traditional fabrics, offering a solution that is not only practical but also versatile. As the demand for high-performance textiles continues to rise, understanding and appreciating the intricacies of this manufacturing process will undoubtedly lead to more innovative applications in various industries. The anti-slip polyester fabric stands as a testament to how modern technology can transform everyday materials into reliable, high-functioning solutions for a safer and more comfortable experience.

English

English Español

Español

.jpg?imageView2/2/format/jp2)