Digital printing has revolutionized the textile industry, particularly in the realm of polyester fabrics, known for their vibrant colors and intricate designs. One key aspect of this technology is the production speed, which directly influences the overall cost of fabric. Unlike traditional printing methods, which can churn out large quantities of fabric quickly, digital printing operates at a slower pace. This slower production speed arises from the intricacies involved in preparing the designs, calibrating the printers, and ensuring that the high-quality standards are met. The precision required for clear, lifelike patterns means that the machinery must work meticulously, adding time to the overall process.

As a result of this slower speed, the cost of producing polyester digital printing fabric tends to be higher than that of fabrics printed using traditional methods. While traditional printing can benefit from economies of scale, allowing for mass production at lower costs, digital printing requires a more individualized approach. Each design often needs specific setups, and this customization can lead to increased labor costs and longer lead times. Businesses must balance the desire for unique, high-quality prints with the realities of production costs. Consequently, digital printing is often viewed as a high-end solution, appealing to markets where premium quality and distinctive designs are paramount.

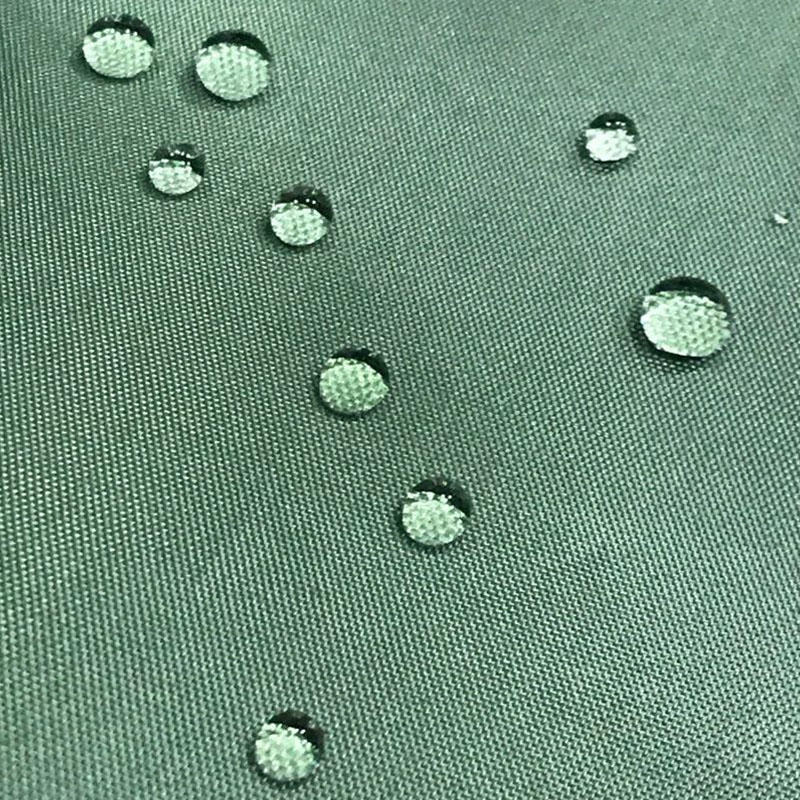

Moreover, the investment in digital printing technology itself can be substantial, encompassing both the equipment and the materials used, such as specialized inks that are suitable for polyester. This initial investment must be recouped through pricing strategies, further contributing to the higher costs associated with digitally printed fabrics. Despite these challenges, the market has shown a growing demand for polyester digital printing fabrics due to their exceptional qualities, including high color fastness and durability, which are crucial for consumers seeking longevity in their textiles.

While the slower production speed of digital printing results in increased costs, this method offers unique benefits that cater to high-end markets and specialized applications. As the industry continues to evolve, balancing production efficiency with quality will remain a central focus for manufacturers looking to optimize their offerings in the competitive landscape of textile production.

Digital printing has revolutionized the textile industry, particularly in the realm of polyester fabrics, known for their vibrant colors and intricate designs. One key aspect of this technology is the production speed, which directly influences the overall cost of fabric. Unlike traditional printing methods, which can churn out large quantities of fabric quickly, digital printing operates at a slower pace. This slower production speed arises from the intricacies involved in preparing the designs, calibrating the printers, and ensuring that the high-quality standards are met. The precision required for clear, lifelike patterns means that the machinery must work meticulously, adding time to the overall process.

As a result of this slower speed, the cost of producing polyester digital printing fabric tends to be higher than that of fabrics printed using traditional methods. While traditional printing can benefit from economies of scale, allowing for mass production at lower costs, digital printing requires a more individualized approach. Each design often needs specific setups, and this customization can lead to increased labor costs and longer lead times. Businesses must balance the desire for unique, high-quality prints with the realities of production costs. Consequently, digital printing is often viewed as a high-end solution, appealing to markets where premium quality and distinctive designs are paramount.

Moreover, the investment in digital printing technology itself can be substantial, encompassing both the equipment and the materials used, such as specialized inks that are suitable for polyester. This initial investment must be recouped through pricing strategies, further contributing to the higher costs associated with digitally printed fabrics. Despite these challenges, the market has shown a growing demand for polyester digital printing fabrics due to their exceptional qualities, including high color fastness and durability, which are crucial for consumers seeking longevity in their textiles.

While the slower production speed of digital printing results in increased costs, this method offers unique benefits that cater to high-end markets and specialized applications. As the industry continues to evolve, balancing production efficiency with quality will remain a central focus for manufacturers looking to optimize their offerings in the competitive landscape of textile production.

English

English Español

Español

.jpg?imageView2/2/format/jp2)