Fabric printing has evolved into a sophisticated art, with various methods tailored to the unique characteristics of different materials. Polyester, a popular choice in the textile industry, presents its own set of challenges and opportunities in the printing process.

The Versatility of Fabric Printing Processes:

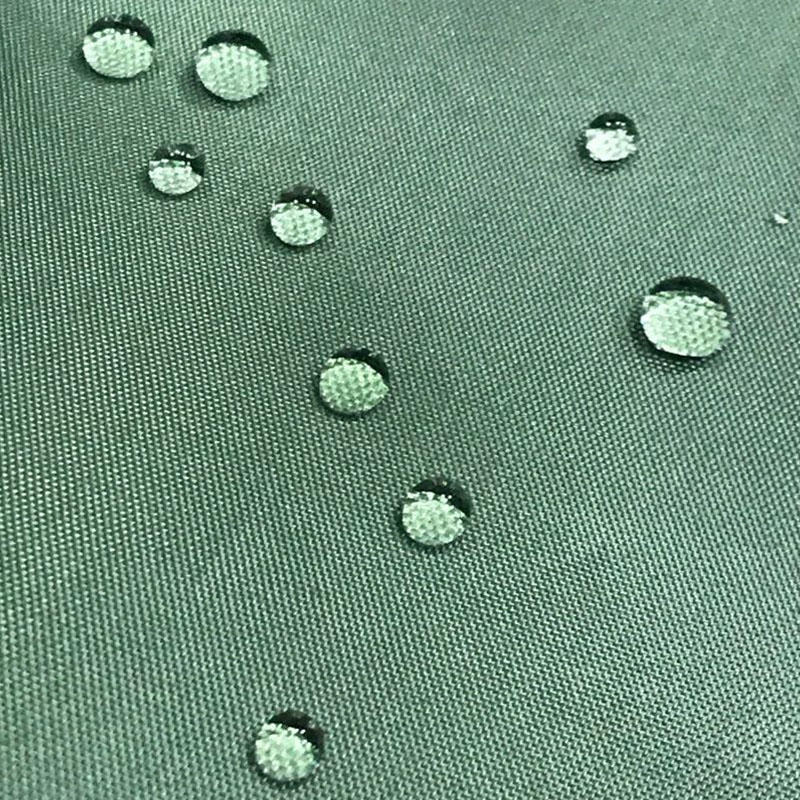

The world of fabric printing encompasses a myriad of techniques, each designed to optimize the inherent qualities of specific materials. Polyester, a synthetic fabric known for its durability, moisture-wicking properties, and vibrant color retention, demands a specialized approach to printing. Manufacturers must consider factors such as the fabric's composition, desired effects, and the intricacy of the design before selecting a printing method.

Sublimation Printing: A Technological Marvel

One of the most prevalent techniques for printing on polyester is sublimation printing. This method relies on a unique process where heat and pressure are used to transform a solid dye into a gas without passing through the liquid phase. The gaseous dye then permeates the polyester fibers, resulting in a long-lasting, vibrant print.

Sublimation printing offers numerous advantages, including exceptional color reproduction, resistance to fading, and a soft feel to the fabric. This method is particularly popular for sportswear, activewear, and other applications where durability and vibrant colors are essential.

Direct-to-Fabric Printing: Precision and Detail

Another method gaining traction in the printing of polyester fabric is direct-to-fabric printing. This technique involves applying the ink directly onto the fabric's surface, allowing for intricate details and precise designs. Advanced technology enables manufacturers to achieve high-resolution prints with a wide spectrum of colors.

Direct-to-fabric printing is a versatile option for polyester, offering the flexibility to create custom designs and intricate patterns. This method is well-suited for applications such as fashion apparel, home textiles, and promotional items where design intricacy is a key consideration.

Screen Printing: Traditional Craftsmanship Meets Modern Innovation

While newer technologies have gained prominence, traditional methods like screen printing continue to be employed in the printing of polyester fabrics. Screen printing involves passing ink through a mesh or stencil onto the fabric. This method is known for its cost-effectiveness and ability to produce bold, opaque prints on a variety of materials, including polyester.

Screen printing on polyester allows for a range of finishes, from matte to glossy, providing manufacturers with creative flexibility. While not as intricate as some digital methods, screen printing remains a viable choice for bulk production and designs that prioritize simplicity and boldness.

Conclusion:

In the realm of fabric printing, the selection of the most suitable method for polyester printed fabric is crucial to achieving the desired results. Sublimation printing, with its ability to infuse colors deep into the fabric, stands out as a preferred choice for activewear and sportswear. Direct-to-fabric printing offers precision for intricate designs, making it an ideal option for fashion and promotional items. Meanwhile, screen printing, with its traditional roots, remains a cost-effective solution for bulk production.

Ultimately, the choice of printing method depends on the specific requirements of the project, the intended use of the fabric, and the desired visual impact. As technology continues to advance, the landscape of fabric printing on polyester is likely to witness further innovations, pushing the boundaries of creativity and quality in the textile industry.

English

English Español

Español

.jpg?imageView2/2/format/jp2)