In the ever-evolving landscape of textile printing, digital printing on polyester fabric stands out as a game-changer, offering unparalleled precision, vibrancy, and customization. However, while the benefits are undeniable, it's essential to delve into the factors that contribute to its higher production cost.

Equipment Costs: One of the primary drivers of the elevated production cost lies in the specialized equipment required for digital printing on polyester fabric. Unlike traditional printing methods, digital printing demands advanced printers specifically designed to handle synthetic fibers like polyester. These machines incorporate cutting-edge technology, including precision inkjet nozzles and sophisticated color management systems, which inevitably come with a hefty price tag.

Ink Costs: Another significant contributor to the higher production cost is the specialized ink formulations necessary for digital printing on polyester fabric. These inks are meticulously engineered to adhere to synthetic fibers effectively and withstand subsequent heat setting processes. While traditional printing methods may utilize more generic ink types, digital printing requires ink formulations tailored for optimal performance on polyester, often resulting in higher costs per print.

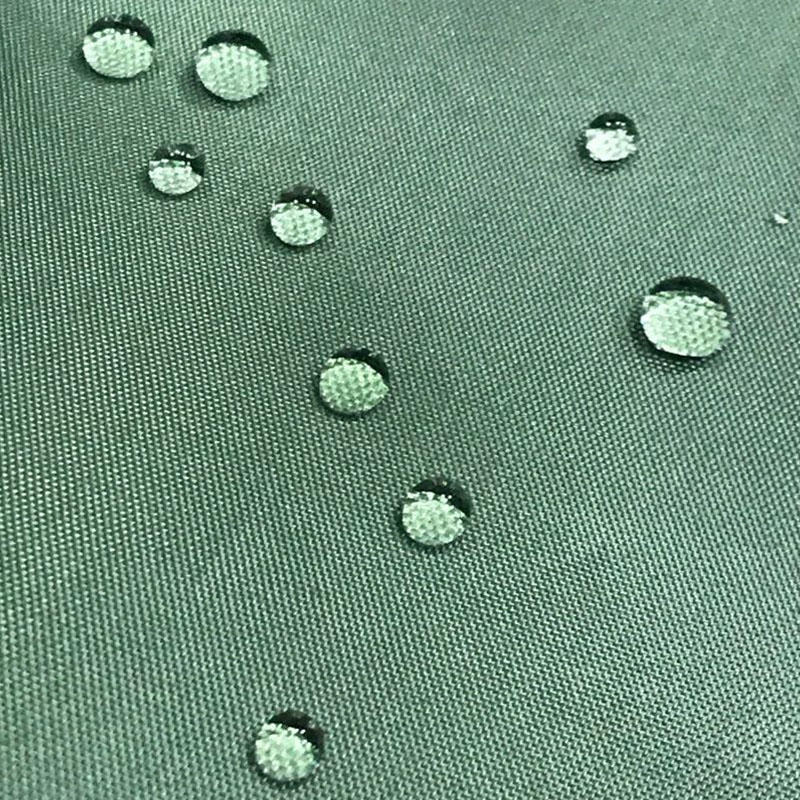

Preparation and Setup: Digital printing on Polyester Digital Printing Fabric involves several preparatory and post-processing steps that add to the overall production cost. Before printing can commence, the fabric must undergo pre-treatment to ensure proper ink absorption and color vibrancy. Additionally, post-processing steps such as steaming or heat setting are necessary to fix the colors permanently. These additional preparation and setup processes require time, labor, and specialized equipment, contributing to the overall cost of production.

Labor Intensity: While digital printing offers advantages such as customization and shorter production runs, it can also be more labor-intensive compared to traditional printing methods. Complex designs or multiple color variations may require skilled technicians to oversee the printing process, increasing labor costs. Additionally, maintaining quality control throughout the production process necessitates meticulous attention to detail and human supervision, further adding to labor expenses.

Waste Reduction: Digital printing on Polyester Digital Printing Fabric is often lauded for its ability to minimize waste compared to traditional methods like screen printing. However, the technology and processes employed to achieve this waste reduction come with their own set of costs. Precision inkjet nozzles and efficient color management systems are essential for minimizing ink waste and ensuring consistent color accuracy, but they require upfront investments that contribute to the overall production cost.

Environmental Considerations: In response to growing environmental concerns, some digital printing technologies offer eco-friendly alternatives to traditional methods by reducing water and chemical usage. While these sustainable practices align with environmental goals, they often involve additional investments in equipment or materials, further elevating production costs.

English

English Español

Español

.jpg?imageView2/2/format/jp2)