In the realm of functional textiles, anti-slip polyester fabric stands out for its versatile applications and robust performance characteristics. This specialized fabric is crafted through a meticulous manufacturing process designed to imbue it with essential properties that cater to both practical and aesthetic needs across various industries.

The production of anti-slip polyester functional fabric typically begins with the selection of high-quality polyester fibers, known for their durability, elasticity, and resistance to abrasion. These fibers serve as the foundational material, chosen specifically for their ability to withstand repeated use and maintain structural integrity under varying conditions. Polyester is favored not only for its strength but also for its ease of processing, allowing manufacturers to achieve consistent quality and uniformity in the fabric's composition.

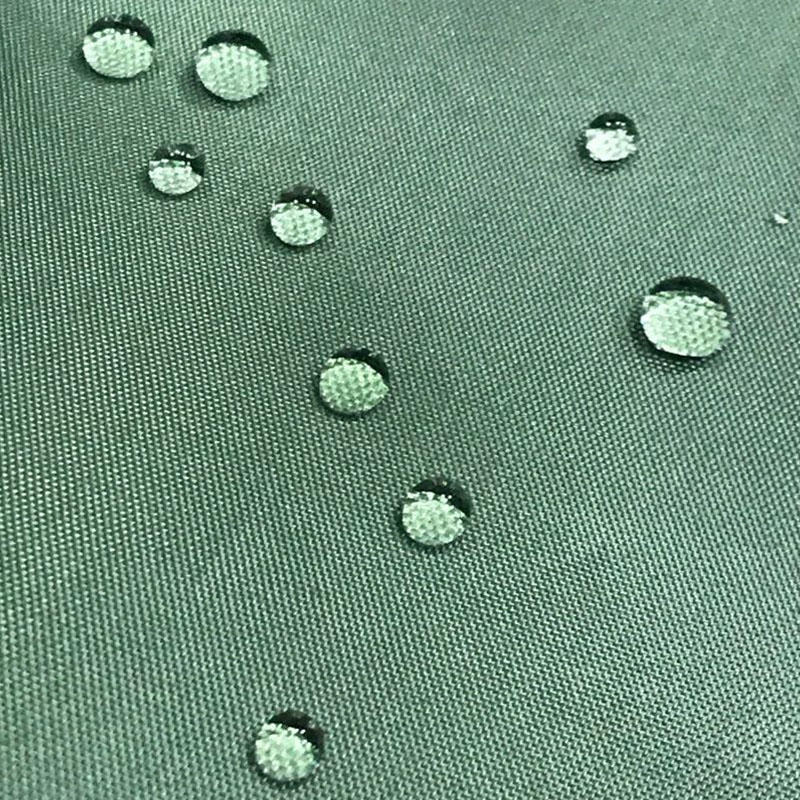

The anti-slip functionality of this fabric is achieved through a specialized treatment process. One common method involves the application of a silicone rubber coating. This coating is applied to the surface of the polyester fabric in a controlled manner, using advanced techniques to ensure even distribution and adherence. Silicone rubber is chosen for its remarkable properties: after undergoing vulcanization—typically through heat curing—it transforms into a soft, elastic material that adheres firmly to the polyester fibers. This transformation not only enhances the fabric's grip but also imbues it with water resistance, oil resistance, and ease of cleaning, making it suitable for environments where slip resistance is crucial.

Advantages of anti-slip polyester functional fabric extend beyond its tactile properties. Its high elasticity allows it to conform to various shapes and surfaces, providing stability and safety in applications ranging from household mats to sports equipment. The fabric's durability ensures longevity, capable of withstanding frequent use without deformation or loss of anti-slip effectiveness. Moreover, its resistance to mildew and moth damage makes it ideal for prolonged use in diverse settings, from domestic interiors to outdoor recreational gear.

Manufacturers employ rigorous quality control measures throughout the production process to ensure the fabric meets stringent standards for performance and safety. This includes testing for adherence to anti-slip specifications, durability under stress, and environmental sustainability. By adhering to these standards, producers not only enhance the reliability of their products but also contribute to the fabric's reputation as a dependable choice in industries where safety and durability are paramount.

In conclusion, the manufacturing process behind anti-slip polyester functional fabric integrates advanced materials and precision techniques to create a product that combines practical functionality with enduring quality. From the selection of polyester fibers to the application of silicone rubber coatings, every step is carefully orchestrated to maximize performance and user satisfaction. Whether used in household articles, sports equipment, or industrial settings, this fabric exemplifies innovation in textile engineering, offering a reliable solution to the challenge of slip resistance in diverse environments.

English

English Español

Español

.jpg?imageView2/2/format/jp2)