Applying pearlescent pigment powder to polyester fabric involves a precise and intricate process designed to achieve a visually striking effect. The core steps include the preparation of the fabric, the application of the pearlescent pigment, and the curing process, each crucial for ensuring the ultimate quality and durability of the finished product.

The process begins with preparing the polyester fabric. This involves cleaning the fabric to remove any impurities or residues that could affect the adhesion of the pigment. The fabric is then treated to enhance its surface, making it more receptive to the pearlescent pigments. This step is critical as it ensures an even application and maximizes the sheen and sparkle effect.

Next, the pearlescent pigment powder is mixed with a suitable printing base or binder. The choice of binder is essential as it affects the pigment's adherence to the fabric and the overall vibrancy of the print. The pigment mixture is then applied to the fabric using various techniques such as screen printing, digital printing, or heat transfer. The application technique chosen can influence the texture and intensity of the pearlescent effect, allowing for a range of visual outcomes from subtle to strikingly glossy.

After applying the pearlescent pigment, the fabric undergoes a curing process. This typically involves heating the fabric to a specific temperature to set the pigment and ensure its durability. Curing is crucial as it helps the pigment bond firmly with the fabric fibers, enhancing the longevity of the pearlescent effect and ensuring that the fabric remains vibrant and shiny even after repeated use and washing.

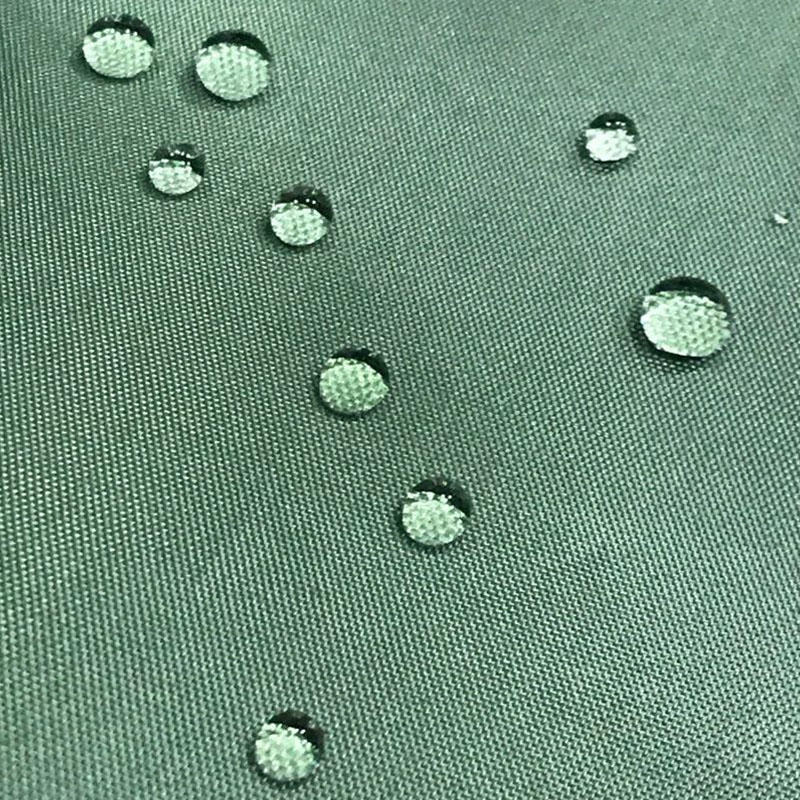

Polyester pearly printing fabric stands out for its luxurious sparkle and visual appeal, making it a popular choice in regions like Russia and Ukraine. The fabric's high-density and wear-resistant properties, combined with its comfort and moisture-absorbing qualities, make it an excellent choice for various applications, from fashion to upholstery. The pearlescent effect not only adds an aesthetic dimension but also contributes to the fabric's allure, creating garments and products that are both visually captivating and durable.

The application of pearlescent pigment powder to polyester fabric involves meticulous preparation, precise pigment application, and careful curing to achieve a high-quality finish. This process ensures that the final product not only looks stunning but also performs well, combining aesthetic appeal with practicality.

English

English Español

Español