Waterproof polyester functional fabrics are engineered to withstand various environmental challenges while maintaining their aesthetic and practical qualities. The coatings and treatments applied to these fabrics are crucial in enhancing their stain-proof and foil-proof characteristics. These treatments primarily involve advanced chemical processes and specialized coatings that work in tandem to provide durability and ease of maintenance.

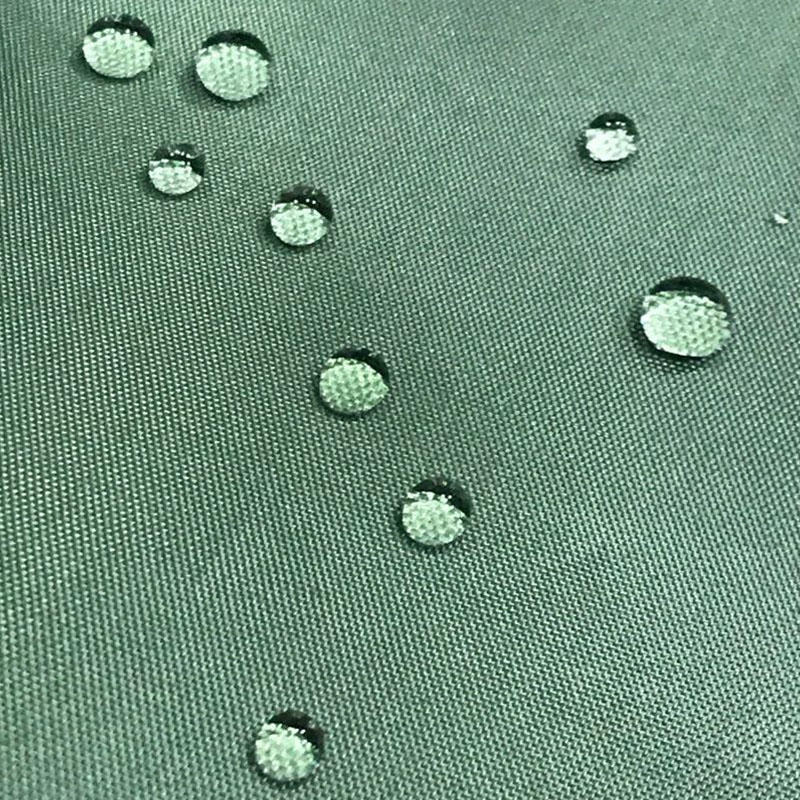

To achieve stain resistance, manufacturers typically apply fluoropolymer-based treatments to polyester fabrics. Fluoropolymers create a hydrophobic barrier on the fabric's surface, which repels water and oil-based stains. This barrier prevents liquids from penetrating the fibers, allowing them to bead up and roll off the surface rather than being absorbed. This technology not only keeps the fabric looking clean but also makes it easier to clean and maintain. The treatment also includes silicone-based agents that enhance the fabric's ability to resist dirt and grime, further contributing to its stain-proof nature.

In terms of foil-proofing, which refers to preventing the fabric from being damaged or compromised by foil-like materials, the approach involves the application of robust, protective coatings. One common method is to use acrylic or polyurethane coatings, which create a protective layer over the polyester fibers. These coatings are designed to resist abrasion and prevent foil-like substances from sticking to or embedding in the fabric. They also contribute to the fabric's overall durability, reducing the likelihood of wear and tear over time. Additionally, these coatings help in maintaining the fabric's high color fastness and resistance to fading, ensuring that it retains its appearance and functionality even after extensive use.

Both stain-proof and foil-proof treatments are engineered to withstand multiple washes, as indicated by the fabric's ability to maintain these properties after up to 30 washes. This is achieved through the use of high-quality raw materials and advanced chemical formulations that bond effectively with the polyester fibers, ensuring long-lasting performance. The combination of fluoropolymer and acrylic or polyurethane coatings ensures that the fabric remains functional and visually appealing, making it suitable for a variety of applications, from outdoor textiles to children's bedding.

The coatings and treatments used on Waterproof polyester functional fabrics are integral to their performance. Fluoropolymer treatments provide stain resistance by repelling water and oils, while acrylic or polyurethane coatings offer protection against foil-like substances and enhance durability. These advancements ensure that the fabric not only meets but exceeds the expectations of both commercial and personal use.

English

English Español

Español

.jpg?imageView2/2/format/jp2)