Industry knowledge

How to choose different processing methods for the production process of Polyester Printed Fabric for different products?

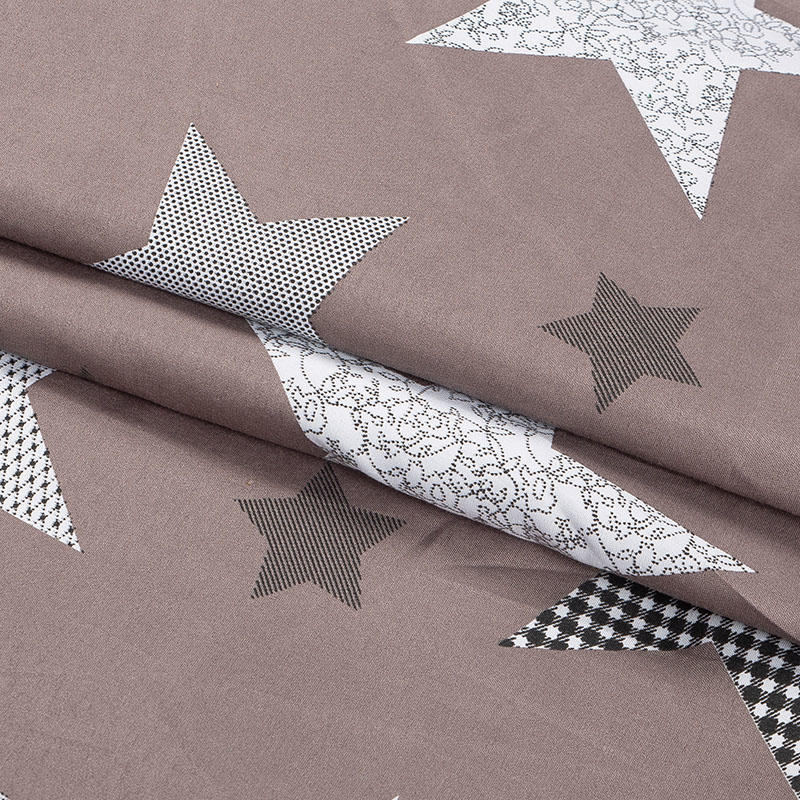

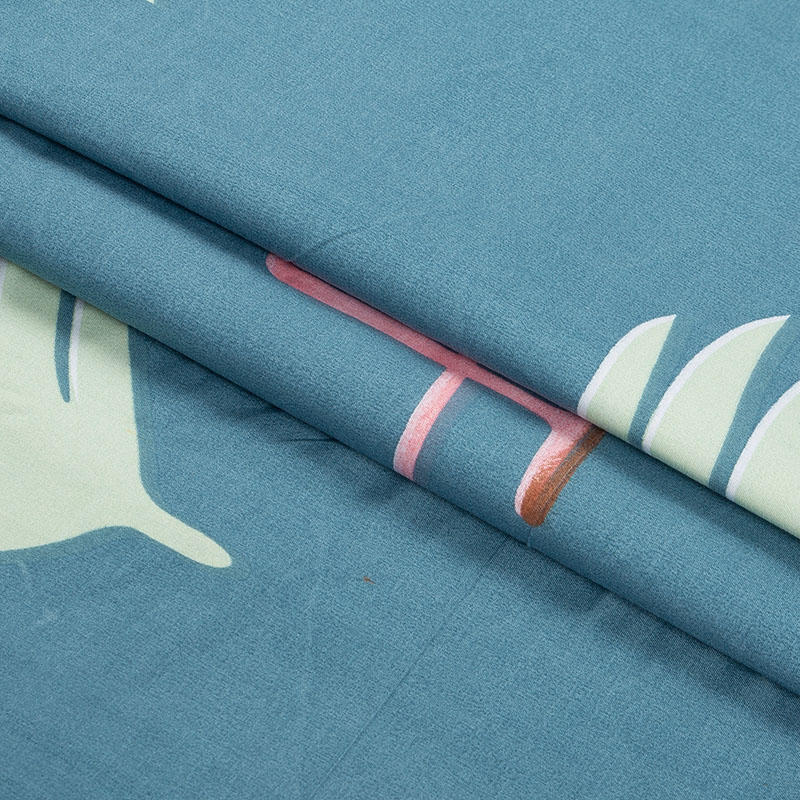

The world of textile production is an intricate tapestry where choices in processing methods significantly impact the outcome of the final product. When it comes to

Polyester Printed Fabric, the decision-making process extends beyond design preferences to include considerations such as dye materials, printing processes, and the desired characteristics of the end product. In this article, we unravel the complexities of choosing different processing methods for polyester printed fabrics, exploring the nuances that dictate decisions in this vibrant and dynamic industry.

Diversity in Dye Materials:

Polyester Printed Fabric production begins with the selection of dye materials, a choice that sets the foundation for the entire printing process. The variation in dye materials leads to distinct types of printing, including pigment printing, reactive printing, and disperse printing. Each of these printing methods offers unique characteristics, influencing the final appearance, hand feel, and color fastness of the printed fabric.

Pigment Printing: Known for its versatility, pigment printing involves the use of color pigments that are mechanically attached to the fabric. This method is lauded for its vibrant colors and durability, making it a popular choice for a wide range of polyester products.

Reactive Printing: Reactive printing utilizes dyes that chemically react with the fabric, forming a permanent bond. This method often results in a soft hand feel and excellent color fastness, making it suitable for products where comfort and durability are paramount.

Disperse Printing: In disperse printing, dyes are dispersed in a liquid and then applied to the fabric. This method is particularly effective for polyester fabrics, offering vivid colors and good resistance to fading.

Diverse Printing and Dyeing Processes:

Beyond dye materials, the choice of printing and dyeing processes further refines the production of Polyester Printed Fabric. Different processes include flat screen printing, circular screen printing, transfer printing, and digital printing. Each method introduces distinct characteristics to the fabric, shaping the visual appeal and functionality of the end product.

Flat Screen Printing: This traditional method involves using a flat screen to transfer the desired pattern onto the fabric. Flat screen printing is known for its precision and is suitable for intricate designs.

Circular Screen Printing: In contrast to flat screen printing, circular screen printing utilizes a cylindrical screen. This process is advantageous for continuous patterns and large-scale production, offering efficiency without compromising quality.

Transfer Printing: Transfer printing involves creating a design on a paper or film and then transferring it onto the fabric through heat and pressure. This method is celebrated for its ability to reproduce intricate details and is often employed for complex and colorful designs.

Digital Printing: Leveraging cutting-edge technology, digital printing allows for direct application of colors onto the

Polyester Printed Fabric. This method offers unparalleled design flexibility and is ideal for short production runs and customized designs.

Considering the End Result:

The choice of processing method for Polyester Printed Fabric is ultimately guided by the desired outcome. Factors such as the intended use of the fabric, design intricacies, and the importance of color fastness play a pivotal role in decision-making. For instance, products with high wear-and-tear may benefit from reactive printing, while intricate designs might find a perfect match in digital printing.

Conclusion:

Choosing the right processing method for Polyester Printed Fabric is a delicate balancing act, requiring an understanding of dye materials, printing processes, and the desired characteristics of the end product. As the textile industry continues to evolve, manufacturers and designers find themselves at the intersection of art and technology, exploring new possibilities and pushing the boundaries of creativity. The journey of selecting the perfect processing method is an art form in itself, contributing to the rich tapestry of textiles that surround us in our daily lives.

English

English Español

Español

Quality

Quality Experience

Experience Prolificacy

Prolificacy Service

Service